Testing Methods

There are various methods by which to evaluate zipper strength.

The basic strength can be determined based on the results of the following inspection methods, from which overall strength appropriate for respective uses can be judged.(Based on JIS-S3015 and ASTM D2061)(Tensile tester: Tensile velocity is 300mm/min. Clamp width is 25mm)

-

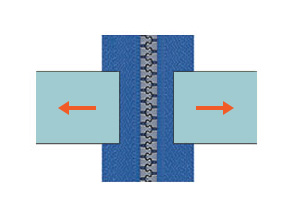

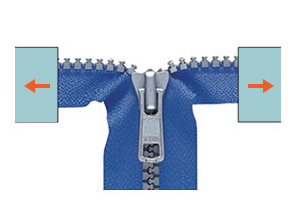

Chain crosswise strength

Chain crosswise strengthTo determine ordinary zipper strength: a zipper chain is interlocked, pulled at a fixed speed at a right angle to the chain interlocked direction, and the resistance is measured.

-

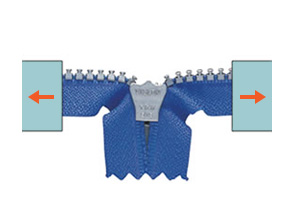

Top stop holding strength

Top stop holding strengthThe lower part of an interlocked zipper is fixed and the slider is pulled up to the top stop. Holding strength is measured by pulling the slider tab firmly.

-

Bottom stop holding strength

Bottom stop holding strengthThe slider is pulled down to the bottom stop and single chains are opened to the right and left sides. Bottom stop holding strength and resistance of the elements inside the slider are measured.

-

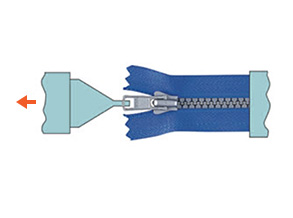

Separating unit crosswise strength

Separating unit crosswise strengthThe open part is fixed to the tensile tester (only the open part as shown in the figure) so that the end of the last element falls into line with the clamp edge and the tensile strength can be measured.

-

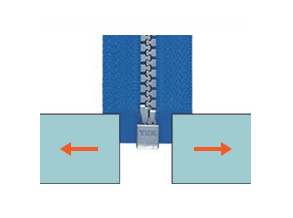

Slider lock strength

Slider lock strengthA slider is locked at the middle of a zipper chain and single chains are opened to the right and left sides. Locking strength and resistance of the elements inside the slider are measured.

-

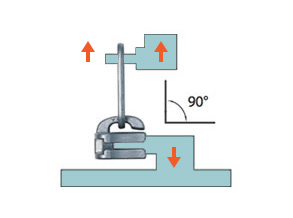

Slider tab pull off strength(90 degrees)

Slider tab pull off strength(90 degrees)For a completed slider, resistance of the slider is measured when the pull tab is fulled away from the lower part of the body. In addition to the 90 degree method of measuring shown in the figure at left, there is one for 45 degrees.